ESSENTIAL CONSIDERATIONS FOR TIMEPIECE MAINTENANCE

Mechanical watches are meticulously crafted to endure the test of time, designed to span generations while maintaining their intrinsic value. To safeguard the enduring legacy of your cherished timepiece, it is imperative to engage in regular maintenance services, ideally every three to five years. This routine upkeep ensures that your watch remains in optimal working condition, preserving its original quality for years to come.

The imperative for periodic servicing extends to Quartz watches as well. Despite their electronic components, Quartz watches feature wheels and gears that necessitate regular maintenance. The batteries powering these watches typically endure only 12 to 18 months, mandating timely replacements to avert the potential hazards associated with battery leakage, which could inflict considerable damage to the watch.

Consider this: your timepiece meticulously records 86,400 seconds daily, unfailingly, year after year. Over five years, the balance wheel rim traverses an impressive 38,000 kilometres. Comprising more than 150 intricately moving parts, your watch demands meticulous attention and superior maintenance, a level of care only achievable through the expertise of a highly skilled and dedicated watchmaker.

ENHANCEMENT SERVICES

Explore our array of enhancement services designed to elevate your timepiece to new heights of sophistication:

1. Dial Refurbishment

Renew and revitalise the appearance of your watch through our expert dial refurbishment services.

2. Customisation of Dial with Diamonds, Pave, Mother of Pearl and Stones

Personalise your watch with bespoke adornments, including diamonds, pave, mother of pearl, and a selection of exquisite stones.

3. Diamond Customisation on Bezels, Bands & Cases

Elevate the aesthetic appeal of your timepiece with our precision diamond customisation options, available for bezels, bands, and cases.

SERVICE WARRANTY INFORMATION

1. Complete Overhauled Watches

Enjoy peace of mind with a service warranty of up to five years for watches that have undergone a complete overhaul, subject to specified terms and conditions.

2. Partial Jobs

Please note that partial jobs are not covered under the service warranty, emphasising the importance of complete overhaul for optimal longevity and performance.

Entrust your timepiece to our Swiss-trained artisans, ensuring a legacy that transcends time.

SERVICING YOUR TIMEPIECES

THE INITIAL EXAMINATION

Before your watch is being serviced, our highly skilled Bonfield-trained watchmakers will conduct a thorough diagnostic examination of the watch to determine the exact servicing procedures that are required to restore the watch back to its original high performance standard.

MOVEMENT MAINTENANCE SERVICE

Microscopic examination

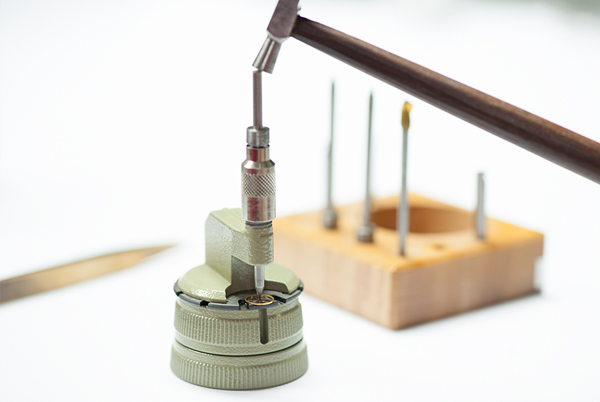

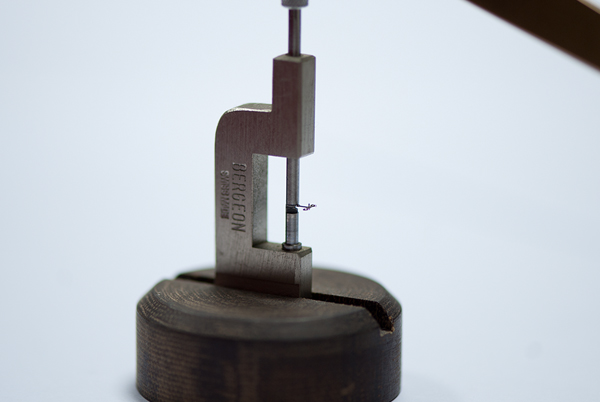

"Platax" Tool - Removing roller and balance staff

Staking Tool - Replace balance staff

Seitz Jewelling Tool - Micrometer adjustment of set jewel permitting correction of endshake

Our watchmaker begins the service process by completely disassembling the watch movement. Each precise part is carefully examined under a 10x magnifying microscope for wear & tear or damage, and will be replaced or refurbished if deemed necessary.

Dried oils / contaminants are then removed from all parts by a series of ultrasonic cleaning processes.

CASE AND BRACELET REFURBISHING

Felting - To eliminate scratches with abrasive paste

Polishing of the back case

Sandblasting of the case

Lapping - The bevels are reground and polished

Your watch casing is carefully disassembled and all gaskets / o-rings are replaced. If necessary, the crystal, crown and any worn parts will also be replaced to ensure that the watch remains completely waterproof.

The watch case and bracelet are put through an ultrasonic cleaning process to remove particles that can oxidise the case and bracelet.

The case and bracelet are then meticulously refinished. Techniques of bevelling, lapping, polishing, brushing, sandblasting and circular-graining to remove dents and scratches are employed so as to restore the case and bracelet to its original lustre.

REASSEMBLING THE MOVEMENT

Reassembling of the watch movement

Lubricating the movement - Each pivot of the watch train wheels and balance staff are lubricated with recommended high grade lubricants

Our watchmaker will proceed to reassemble the movement; an operation which requires extreme dedication as it is both a highly delicate and time-consuming task. This step has to be conducted with painstaking care. Specially formulated oils and lubricants are applied in exactly the right quantities to achieve optimal performance of the movement.

CALIBRATION AND TIMEKEEPING

Timing calibrations - Balance wheels are meticulously timed

Witschi "Watch Expert" - Measures the rate accuracy, amplitude and the beat error of mechanical watches

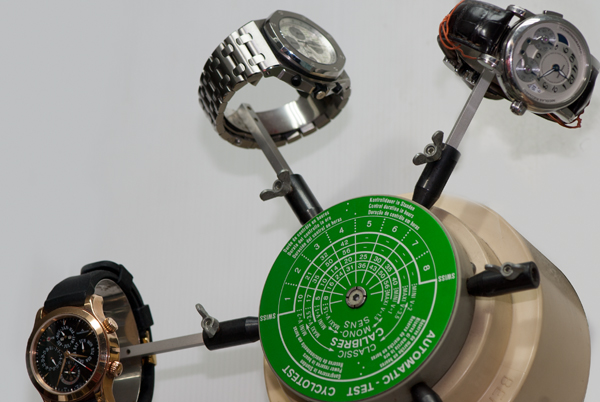

Wrist Motion Simulator - Testing the winding mechanism and the power reserve of automatic watches

Demagnetisation

After re-assembly, the movement is carefully calibrated by adjusting the balance wheel, which is also the "heart of the movement", and the hairspring which oscillates it. The performance and daily accuracy of the movement are then tested in required positions on a sophisticated timing machine to ensure that they are set to the required high-performance standards.

Finally, the dial, hands and rotor self-winding mechanism are fitted back in their positions, and the movement is returned to the case. The newly assembled watch will undergo 5 continuous days of testing, on a wrist-motion simulator, which recreates the normal activities that the watch may encounter when worn on your wrist.

PRESSURE TESTING

Pressure Testing - Waterproof watches are pressure tested to 330 feet

The watch will now undergo a final pressure test in a special vacuum tank. This ensures that the waterproof qualities of the watch are retained in accordance with stringent factory criteria.

FINAL INSPECTION

Final Inspection will be the most stringent check point conducted by the trained eye and sight of the Bonfield's watchmaker

The final step will see the watch passing the final, systematic and uncompromising meticulous inspection by the watchmaker. Our watchmakers from Bonfield are reputed to be the finest in the industry due to their years of practice, expertise and dedication. When you send your watch to Bonfield, you are assured of uncompromising service and absolute dedication. You can be certain that your watch has been treated with utmost respect, and has been paid the absolute attention to detail.

A LEGACY WORTH PRESERVING

Time shapes everything — it weathers, transforms, and sometimes fades the beauty of what once was. At Bonfield, we believe true artistry should never be lost. Through meticulous restoration and masterful craftsmanship, we honour history, breathe new life into heritage, and ensure beauty endures.

Some things are meant to be revived, not replaced.

Bonfield is equipped with a comprehensive array of the finest Swiss equipment, affording us a distinctive advantage and unparalleled capabilities in the meticulous restoration of both vintage and pocket watches. Our commitment to restoring your cherished and sentimental timepieces is underscored by our dedication to returning them to their original standards of excellence.

Recognising that the restoration of these exceptional vintage pieces demands an investment of time and attention far beyond routine maintenance, Bonfield distinguishes itself by crafting bespoke, hand-made parts for components that are either challenging to procure or no longer available. Our artisans expertly repair and polish steel surfaces, corners of bridges, cocks, and screws, ensuring the comprehensive rejuvenation of your timepieces.

The rarity and specialisation of this skill are underscored by the extraordinary dedication to education and training required. Such artisanal expertise is a distinction held by only a select and exclusive group of watchmakers globally. At Bonfield, we take pride in being part of this distinguished cohort, ensuring that our craftsmanship reflects the pinnacle of precision and artistry in watch restoration.

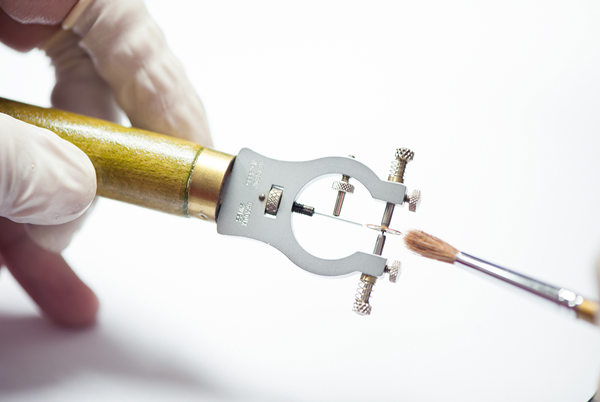

Turing Caliber - Inspect the flatness of balance wheel

Poising Tool - To ensure that the balance wheel is poised or balanced

Reducing the weight of the balance wheel

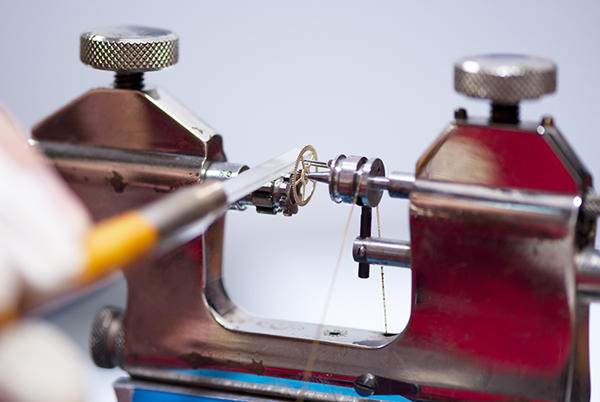

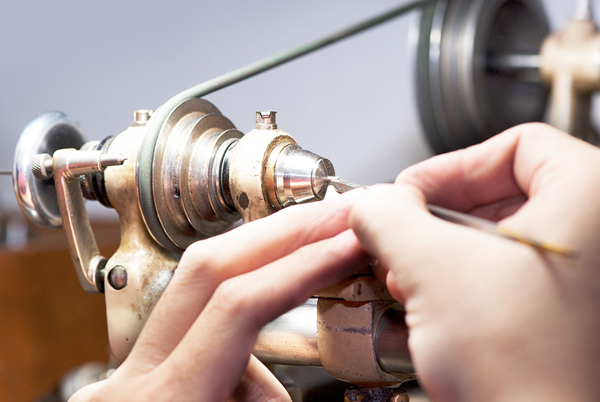

The "Jacot" Pivot Lathe - is used for burnishing pivots of the watch train wheel

Fabrication of precision parts with the aid of the watchmaker's lathe

To forge the guard pins

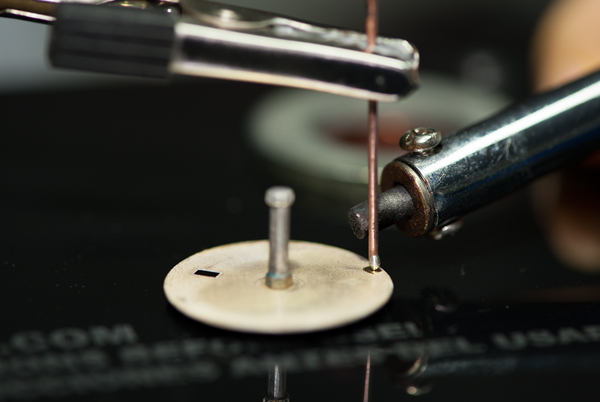

Dial feet restoration

Crystal and glass customisation

Laser spot soldering

SHOWCASE OF RESTORATION WORK

The refinishing process is a complex one, starting with the methodical disassembling of the entire watch part by part. In some cases, special tools are developed just to refinish certain case parts. Refinishing has to be done in a separate room so that dust particles do not contaminate the movement of the watch.

Each case part of the watch is polished individually to reinstate its original factory specifications, and only after this does the reassembling of the watch take place. Even the screw heads are polished, such that by the time we are done with the refinishing, your watch will look as new and stunning as the day you first took it home.

These pictures show the refinishing works that we have done for our customers.

PART I    BEFORE    AFTER | PART II      BEFORE      AFTER |

| Sandblasting is a metal-cleaning process which if not done professionally, could lead to some dimensional damages to the watch, i.e., loss of metal from the surface being cleaned. It is an effective cleaning process for hard surfaces by way of using high pressure air. Sandblasting can be used for smoothing, shaping and cleaning hard surfaces. The effect of sandblasting is similar to that of using sandpaper, but the former provides a largely more even finishing. Note the picture below. The timepiece sent in by our customer shows an obvious rough and speckled finishing that is certainly way out of factory's specifications. After our servicing, you will notice a much softer, uniform, matte, clean and bright finish. This is the desired effect and is only made possible by using the correct procedures, methods and tools. The sheen and lustre seen in the "after" picture is associated with factory's specifications. More importantly, there are no dimensional changes in the metal which would ruin the look of the valuable timepiece. |   BEFORE   AFTER |